2/23/21

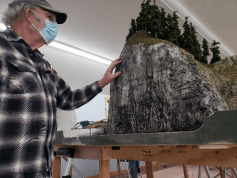

We have some great pictures to share with you in this progress report. Doug, the mayor of Eagle Cove and Grand Poobah of it’s 28 inhabitants, has created his mountain masterpiece for Eagle Point. He has also, unknowingly, re-created a truncated mountain face found several times along the Oregon Coast. That is a mountain, often times over 500 feet high, that meets the ocean at a sharp angle. The wave action over a period of eons wears away the base of the mountain and it starts falling into the ocean. Hard rock like basalt slips off the face in large chunks creating cliffs and softer sedimentary rock just slides down a long slope into the sea. One of these slopes occurs just north of Lincoln City at Roads End Point and is a great source of landscape material for model railroaders. You just can’t take it – legally.

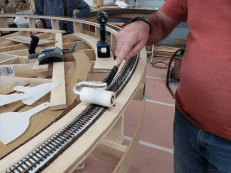

Doug inspects the big cliff at Eagle Point. A long trestle will run along the fascia at the base of this cliff.

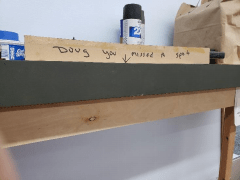

George has been working on the upper level framing, cork and track. His latest efforts are to create the “S” curve opposite Eagle Point in the north room and inserting some of the more memorable scenery from the old layout into the new layout. The picture below shows a chunk of the old “high line” that he’s going to insert in the upper main across from the roundhouse. He also has his eye on the sidehill trestles that Doug built for the old layout. These will probably fit near the “S” curve.

George plans the exact placement of a piece of the old layout

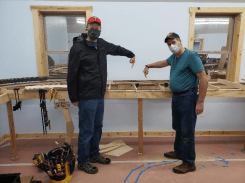

Patrick came by this week and started to plan Corvallis. We will support him by building the basic benchwork and then he will work his downtown magic to create some city scenes. He has some great ideas. I don’t know if they’re classified or not so, in the future, we may be able to share them with you. In addition to these, he also keeps up with expenditure reimbursements and spending allocations. Thank you Patrick.

Gene continues to work on track joints. He has become best friends with Walther’s code 83 rail joiners. He had a bunch to start with and we ordered 8 more packages of 50 each. That was enough? Nope. He just told me today that he needs 8 more packages!

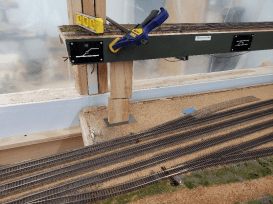

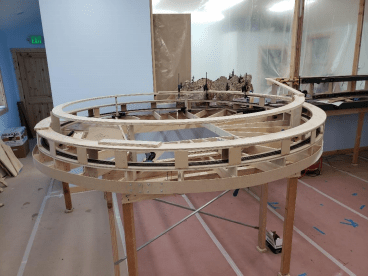

The helix as of 2/24/21. Starting from the bottom up: temporary MDF fascia to stabilize the end of stringers, first loop with roadbed and track laid in (this will be visible as the “inside of a tunnel”; second loop with sub-roadbed only will be scenicked; third loop mock-up with reduced radius set inside other loops also scenicked. Grades are 1.4% and 1.6% and radii are 49” and 45” respectively. Reverse loop will be set at bottom level and hidden like on the old layout. Note BIG BRIDGE mock-up in upper right hand corner crossing over to Blodget – probably a Micro Engineering tall steel viaduct (any takers??) We should be laying helix track next week.