11/10/20

Work continues on the layout rebuild as we set L girders, add legs as appropriate, figure grades and place additional layout chunks in place. This week we made good progress as McDonalds on 9th street came to know our order before we placed it. Our group has thinned out a bit as Covid facts weigh in and some members respond to these concerns. We respect these responses and will continue to work as virus numbers and Adair Village policy allows. Please understand that County responses to the pandemic may require all of us to suspend work. We do have a plan “B” however, and that is to do pre-cuts (pieces fabricated in home shops and brought to the layout for later installation) in our home shops such that they will be ready when things start up again. We haven’t heard about any shut downs but we are ready.

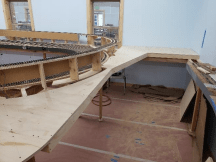

Final alignment process on the Eagle Cove/Eagle point section

Doug and Gene worked for two days to complete framing below Eagle Cove and Eagle Point. Additionally they attached the harbor, helix, and turntable yard chunks together to form one large layout piece. This is a complex process made easier by nicely leveled L and T girders. Some adjustments were necessary but layout joints are looking good with only minimal – less than 1/16”—adjustments required for smooth track. Congrats to these two guys who are pioneering reassembly processes. As they sharpen their skills we will develop many more opportunities for them to demonstrate their expertise.

Lonnie, Vic, and George assembled additional L girders for use in the south room. They had quite a process going on as they clamped, glued, air nailed and screwed them together. The original L girders were getting pretty well picked thru as we used them up in the north room.

We had to hold an impromptu engineering meeting Monday morning regarding an gradient dilemma. This had to do with the difference in floor levels of almost 6”, between the main room and the yard area in the old building. When we rebuilt the layout 8 years ago we accommodated this difference with clever grades on the mainline and a reduced height at Eddyville. Most folks didn’t notice these adjustments. Monday morning these anomalies bit us in the butt. Lively discussion ensued.

The problem was defined as a difference of about 3 inches in the framing leading up to Eddyville. Leaving the yard and going up the Eagle Cove helix was going to require an added rise of over 3” defined as an additional 15 feet of run at 1.7 percent. Several options were discussed including cutting the top off Eagle Mountain, adding another circle to the helix, and replacing the peak. Doug Taylor, builder of the original Eagle Mountain, came close to apoplexy as he almost swallowed his mask and passed out from hyperventilation. 9-1-1 was considered but other options were quickly suggested and color soon returned to Doug’s face. The L girder he had ahold of , however, will forever have his fingerprints embossed in it.

The selected option included continuing the 1.7% grade for another 15 feet into Eddyville. This requires one leg of the staging track wye to be on a grade but the math shows this can be reduced to 1.3% or less. Discussion regarding the need to back up the wye with a long train and subsequent problems with backing on a curve and grade made obvious the need for the staging yard entrance to be bi-directional. It can now be entered either from the east or west and crossovers and a turntable in the yard allow for reversing trains. A side benefit is additional clearance between the upper staging area and lower switching area.

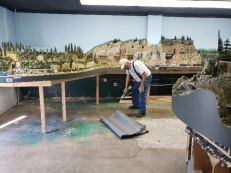

Grievous damage as the result of the blaze

On Tuesday, excitement was ignited among the group by a fire in the shop. The conflagration started in the chop sawdust bag. It was immediately reported by George and quickly dealt with by him running outside in the rain. Other members of the crew attempted to evacuate the building but we’re pretty old and all were laying under the layout. This resulted in a winning scene for America’s Funniest Home Video as 3 old guys tried to gain an upright posture suitable for the evacuation. They grabbed anything to assist in standing up including each other yielding a rather savage scene. Just as they all got to an upright stance satisfactory for evacuation, George came back having gained the upper hand in controlling the blaze. One member, who got up quickly, was seen leaving the scene but later returned with a package of hotdogs from the little store. There were no injuries or damage to the building. The picture above pretty clearly shows damage sustained by equipment.

Subsequent investigation yielded a cause for the incident. A member was using the chop saw, inadvertently nicked a hardened screw, the resulting spark flew into the sawdust bag , slowly smoldered amidst the dried sawdust, finally ignited and blazed forth in all its fury right in front of poor George. The investigation also showed that George reacted well by reporting the incident to Jerry while holding the bag. Jerry, standing next to a fire extinguisher and being a Cajun, sent George somewhere else – outside.